Peptides in Print

A new ink for 3D printing promises bioengineering breakthroughs.

Spring 2023

By Silvia Cernea Clark

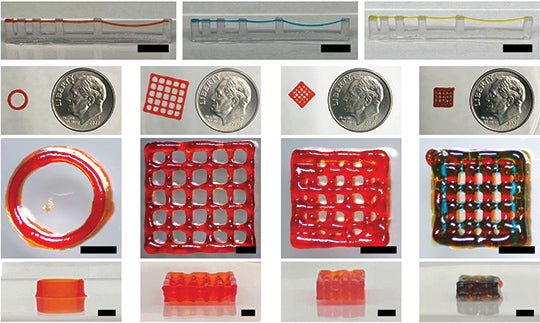

Researchers in Rice’s Hartgerink lab have figured out how to 3D-print well-defined structures, such as lattices, using a peptide ink.

“Eventually, the goal is to print structures with cells and grow mature tissue in a petri dish. These tissues can then be transplanted to treat injuries or used to learn about how an illness works and to test drug candidates,” said Adam Farsheed ’24, a Rice bioengineering graduate student and lead author of the study, which appeared in Advanced Materials.

“There are 20 naturally occurring amino acids that make up proteins in the human body,” Farsheed explained. “Amino acids can be linked together into chains, like Lego blocks. When amino acid chains are shorter than 50 amino acids, they are called peptides.”

Jeffrey Hartgerink, professor of chemistry and bioengineering and associate chair for undergraduate studies, and his collaborators previously developed a class of self-assembling peptides, where “self-assembling” means they can arrange themselves solely based on their structure and composition. These “multidomain peptides” assemble into a hydrogel: a water-based material with a gelatinous texture that can be useful for a wide range of applications such as tissue engineering, soft robotics and wastewater treatment.

Multidomain peptides have been used for nerve regeneration, cancer treatment and wound healing and have been shown to promote high levels of cell infiltration and tissue development when implanted in living organisms.

“What I was looking to do in this project was to show that these peptides are a great 3D-printing ink,” Farsheed said. “It might be counterintuitive since our material is so soft, but I recognized that our multidomain peptides are an ideal ink candidate because of the way they can reassemble after being deformed, similar to how toothpaste forms a nice fiber when pushed out of a tube.”

Farsheed’s mechanical engineering background inspired an unconventional approach to testing his hypothesis.

“Instead of chemically modifying the material to make it more amenable to 3D printing, I tested to see what would happen if I simply added more material,” he said. “I increased the concentration about fourfold, and it worked extremely well.

“There have been only a handful of attempts to 3D-print using other self-assembling peptides, and that work is all great,” Farsheed said, “but this is the first time that any self-assembling peptide system has been used to successfully 3D-print such complex structures.”